Desktop Benchtop Injection Molding Machine 110v 220v Plastic Create Manufacture

Description

Desktop Benchtop Injection Molding Machine 110v 220v Plastic Create Manufacture for sale

Condition: New

Type: Tube Head Injection

Style: Vertical

Plastic Type: Thermoplastic

Automatic: No

Power(W): 400W

Capacity: 1 cu. inch by volume / (aprox.17.5g of PS by weight)

Injection method: Manual

Temperature Range: Room Temp – 400C

Suitable Plastics: PE, PS, PP

Max. Overall Dimension: 9 x 14 x 25 (with handle up)

Packaging Details Standard export wooden case

Manual-Type Small Home Plastic Injection Molding Machine

A small, hand-operated plastic injection molding machine for making prototypes and short-run production.

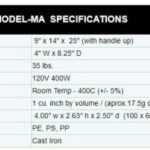

MODEL-MA SPECIFICATIONS

Max. Overall Dimension 9 x 14 x 25 (with handle up)

Frame Footprint 4 W x 8.25 D

Weight 35 lbs.

Electrical 120V 400W

Temperature Range Room Temp – 400C ( /- 5%)

Capacity 1 cu. inch by volume / (aprox.17.5g of PS by weight)

Maximum Mold Size 4.00 w x 2.63 h x 2.50 d (100 x 66 x 63) mm

Suitable Plastics PE, PS, PP

Frame Construction Cast Iron

MODEL- MA FEATURES

1 Cushioned handle grip 10 Thermostat control

2 Handle Lock 11 Thermometer (magnetically mounted)

3 Ram 12 Temperature probe port.

4 Control box 13 Injection nozzle (removable)

5 Power switch with circuit breaker 14 Vise Handle (steel w/ black oxide finish)

6 Pellet Tray 15 Steel backing plate (adjustable position)

7 Heater status indicator light 16 Mold Stop (adjustable position)

8 Enclosure (stainless steel) 17 Power cord

KEY BENEFITS

Saves you money

Whether you make an epoxy mold to reproduce an existing part, or machine an aluminum mold to make a totally new part, you will save money. Even if you have your molds professionally made for you, the cost of making a small mold to fit this machine will be far less expensive than it would be to make one for a production size injection molder.

Saves you time

If you’re an inventor or do any kind of product development work, you’ve probably experienced the fun of having to modify a prototype five, ten or even twenty times until you finally get it the way you want it. With this machine, you can quickly produce multiple variations of your prototypes as quickly and often as you need them, and not have to wait days or weeks for someone else to do it for you.

Makes you money

With this machine you can produce small plastic parts inexpensively and sell them to niche markets. Some examples are: novelty items, custom components for model cars, boats, planes & trains; game pieces; plastic jewelry; keychains; military and fantasy game figures (and modified body parts for them), etc. Not to mention the millions of specialty plastic parts used in industry to fabricate devices, machinery, appliances, tools, electronics, automobiles, etc.

Quality made

We’ve been 4 years in desktop small hand injection machine. It has quality components throughout produced by experienced machinists who take great pride in their work.

Reasonably priced

The cost of this machine is easily justified when you consider the money and development time it saves you can return your investment on your very first project.

Short Info

- Shenzhen, Guangdong, China

- USD

- See all adverts posted by Alvin Peh

- Plastics and Chemicals

- Print this ad

- Seller ref:

Buyers Premium

6% of the final sale price

Location

The safest way to buy a machine online

The Machine Market’s secure payment system protects buyers and sellers. At the end of the sale, the buyer transfers payment into a third-party escrow account. Once the transfer of the machine is complete, both parties confirm they are happy with the sale and the money is released to the seller.